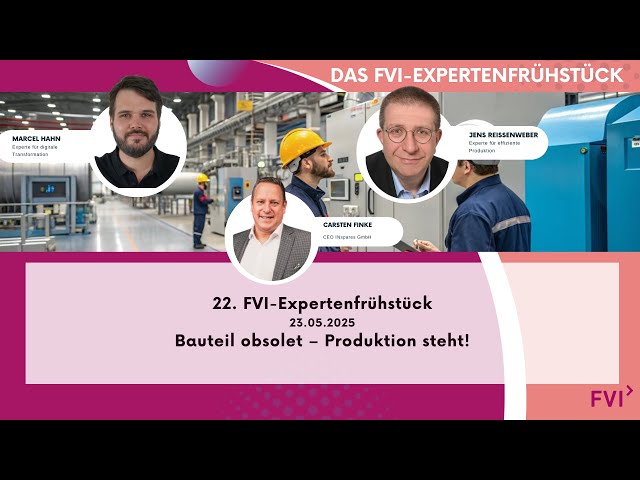

· Marcel Hahn · Events

22nd FVI Expert Breakfast

Component Obsolete – Obsolescence in Maintenance

🔌 “Component obsolete – production stops!” How a single part can bring entire plants to a standstill – and what you can do about it.

At the 22nd FVI Expert Breakfast on May 23, 2025, we’ll tackle a topic almost everyone knows but few approach systematically: Obsolescence in maintenance.

🔍 Spare parts that no longer exist. 📉 Components that were never documented. ⛔ Opaque supply chains, silent failure risks. 👉 And then? Downtime.

🎙 Our guest: ➡️ Carsten Finke, Managing Director of INSpares GmbH, shares real-world experience:

Why you often don’t even know what you’ve got

Why transparency is the most powerful lever against obsolescence

How to shift from “crisis mode” to proactive strategy

📅 When? Friday, May 23, 2025, 09:30–10:30 CEST 🌍 Where? Online – live & interactive

👥 Moderation: 🎤 Marcel Hahn – Moderator & Tech-Enabler 🎤 Jens Reißenweber – Maintenance Consultant & Scout for Perfect Production

💡 What to expect: ✅ Why many machines include obsolete parts from day one ✅ How companies can identify risks – before it’s too late ✅ Real stories, practical insights, and clear strategies

📌 Spoiler: The dead end is coming – but you don’t have to drive all the way there.

Summary

Obsolescence Management Carsten, Marcel, and Jens discussed the importance of obsolescence management in industry. Carsten emphasized the need for transparency regarding installed components to enable strategic decision-making. Jens pointed out that the issue is becoming more urgent, especially as retrofit is the new investment.

- Definition and Significance: Carsten explained that obsolescence management involves managing discontinued parts. It’s not a problem if a part becomes obsolete – as long as you don’t rely on it. In industrial settings, where parts are complex and interconnected, failure can have major consequences.

- Real-World Example: Carsten shared a case where a client discovered in 2019 that parts in a new plant were already unavailable. This led to production downtime and highlighted the need for effective obsolescence management.

- Retrofit as a Solution: Jens highlighted retrofitting – modernizing existing systems – as a key strategy, especially relevant when investing in new equipment isn’t feasible.

Transparency and Lifecycle Data Carsten stressed the importance of transparency regarding installed components and their lifecycle data.

- Component Inventory: All installed components must be identified to create transparency – including manufacturer, configuration, and installation context.

- Lifecycle Tracking: Tracking component lifecycles enables early reaction to discontinuations and proactive planning.

- Customer Example: Repeated case: a new plant (2019) already included obsolete components – leading to downtime.

Procurement Challenges Jörg and Klaus highlighted the challenges SMEs face in sourcing components and managing lifecycle data.

External Support: Jörg noted that SMEs often struggle without external help. Service providers can increase transparency and support lifecycle monitoring.

Monitoring Processes: Klaus emphasized the need for structured processes to track lifecycle data. His company uses a database that flags lifecycle changes and discontinuations.

Strategic Planning and Budgeting Carsten and Jens underscored the importance of strategic oversight in obsolescence management.

- Bird’s-Eye View: Strategic decisions require a comprehensive view of the facility – identifying critical components, planning inventory, and setting priorities.

- Flexibility: Jens stressed the need for adaptable strategies and budgets to respond to unexpected failures or market shifts.

Digitization and AI Support Tina presented two use cases where digital tools and AI help address obsolescence.

- AI for Information Retrieval: AI can extract needed data from digital records – helping technicians find the right parts faster.

- 3D Printing and Machining: Tina described how these technologies are used to reproduce unavailable parts – allowing legacy equipment to remain operational.

Collaboration with Service Providers Roland and Horst emphasized the need for cooperation with external experts.

- Service Provider Support: Roland noted that obsolescence management is not the core business of manufacturers – external specialists are often essential.

- Public Transport Approval: Horst pointed out that system approvals in public transport are a major challenge – and obsolescence must be considered already at procurement.

Experiences and Best Practices Hans-Christian and Marcel shared hands-on insights into dealing with obsolescence.

- Strategic Reserves: Hans-Christian recalled how companies used to keep reserves of critical spare parts – a key tactic to avoid downtime.

- Data Digitization: Marcel emphasized digitizing data assets to create transparency and prepare for obsolescence. Technologies like digital twins can help ensure spare part availability.