· Timo Klingenhöfer · News

Effective monitoring, made simple! With ADAM CMS Sensorbox prototypes

Overview of the current status of the ADAM CMS sensor box

In our daily work in the field of digitalization, we have created a powerful and flexible solution for a variety of use cases with our ADAM platform and the Flow Studio it contains. However, the collection of good and reliable data is essential for successful monitoring, for example of an industrial plant. This often presents us with challenges.

The challenge of data availability

To date, the required data has been provided by the companies using our platform as far as possible. However, this is not always possible to the desired extent. Older systems in particular often do not have sensors that can be read out, and even newer systems do not always provide for this data to be uploaded to a cloud platform.

Solutions for wind turbines

For our HAWIC platform (an application based on our ADAM platform), we are working with our partner Thomas Wilmes Ingenieurbüro on solutions for wind turbines. The so-called wind gateway is used here, which reads relevant data directly from the wind turbine control system (WTCS) and sends it to the cloud. As older WTCs are also equipped with numerous sensors for (almost) complete autonomous control, it is not absolutely necessary to install additional sensors. For other types of system, however, basic data such as ambient temperature and humidity must be retrofitted, as these can have a major impact.

Extension to the IoT gateway

To make retrofitting simple and cost-effective, we are working on expanding the wind gateway into a general IoT gateway. This is largely based on the same hardware as the wind gateway, but will be equipped with additional sensor boxes. Several versions of the sensor boxes are planned to record environmental data or technical parameters such as currents or pressure differences. For easy installation, the boxes are only connected with an Ethernet cable, with power being supplied via PoE (Power over Ethernet). PoE enables the transmission of power and data via a single cable.

Hardware development

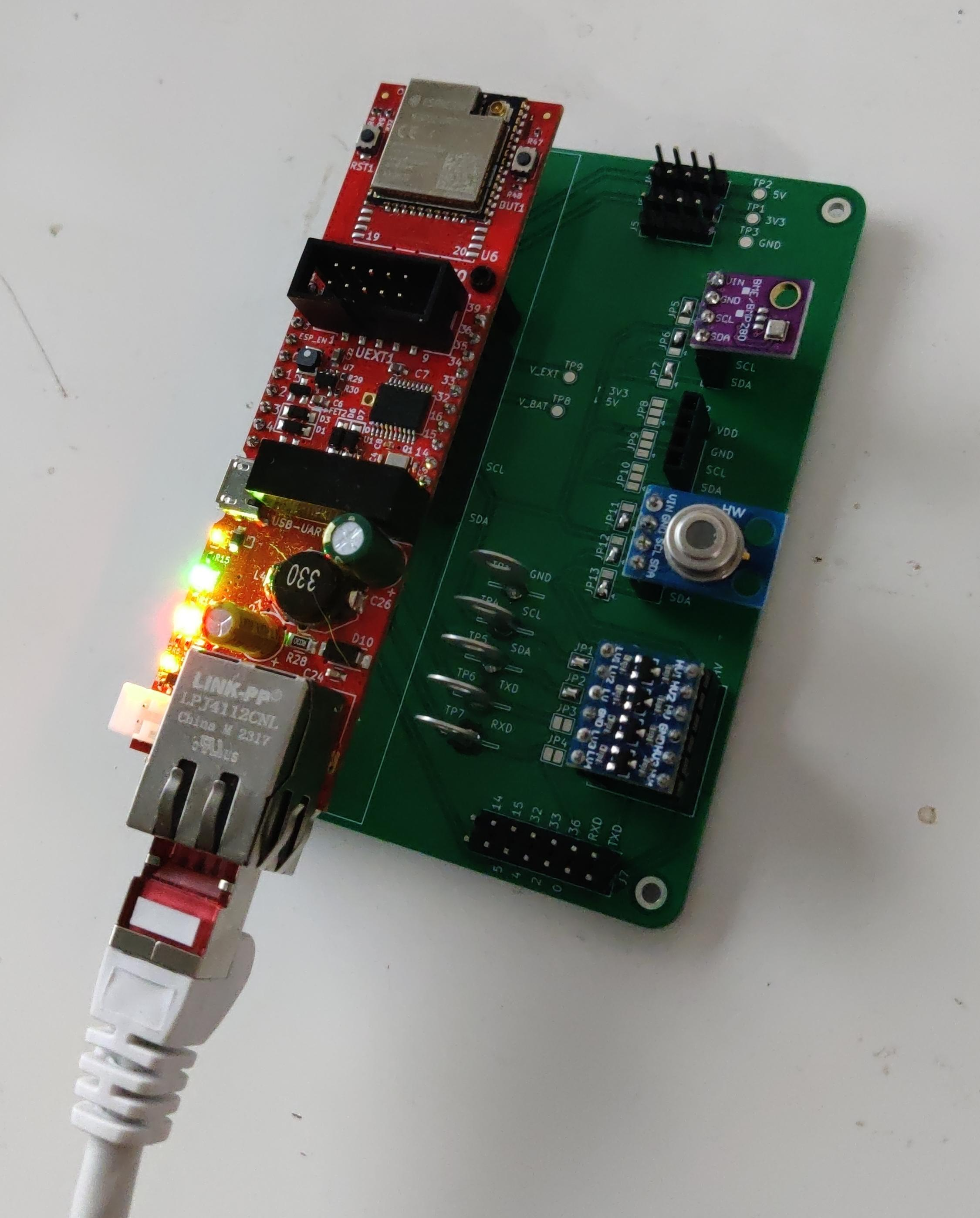

The hardware of the sensor boxes is developed by us on the basis of the ESP32 PoE board from Olimex. We are developing our own PCBs for connections between the ESP32 and the sensors. The current prototype contains slots for I2C sensors, which can be configured for 3.3V or 5V using solder jumpers. There is also a slot for a 4-channel level shifter to translate 3.3V signals into 5V signals. The prototype board is initially designed as a more stable breadboard on which sensor devboards can be connected. In a later “production-ready” version, the sensors will be soldered directly onto the board. For our team, which primarily consists of software developers, getting into hardware development was a new challenge. Thanks to online resources and development instructions from hardware manufacturers, we were able to acquire the necessary knowledge.

Here you can see the ESP32-POE-ISO from Olimex (red PCB on the left), a BME280 (purple PCB top right), an MLX90214 (purple PCB center) and a 4-channel level shifter (purple PCB bottom left).

Summary

By developing the IoT gateway and the corresponding sensor boxes, we are actively helping to create a more reliable database for monitoring industrial plants. Although the process is complex and challenging, our approach shows that it is possible to develop innovative solutions, even if the team originally comes from a different specialist area. Do you have similar challenges in your company? Share your experiences or questions in the comments section below and let’s find the best solutions together! Through continuous improvement and adaptation, we will ensure that our solutions meet the requirements of modern digitalization and Industry 4.0. Stay tuned and follow our progress!